Transiting from Industry 4.0 to industry 5.0

Prof. Arunaditya Sahay

Dean (Research)

Professor of Strategic Management, BIMTECH (View Full Profile)

Background

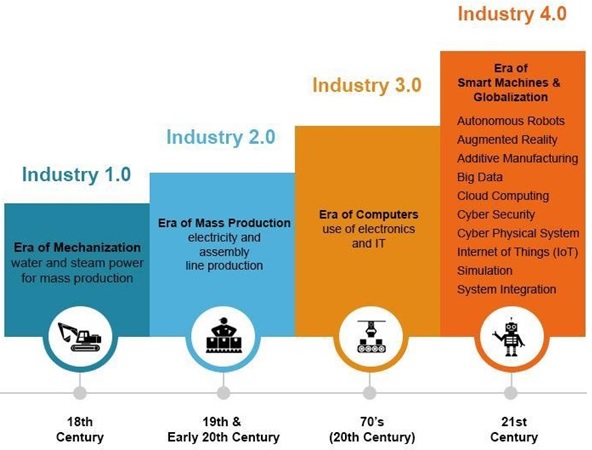

The First Industrial Revolution used water and steam power to mechanize production. The Second used electric power to create mass production. The Third used electronics and information technology to automate production. Now a Fourth Industrial Revolution is building on the Third, the digital revolution that has been occurring since the middle of the last century. It is characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

Today we are in the fourth industrial revolution that was triggered by the development of Information and Communications Technologies (ICT). Its technological basis is smart automation of cyber-physical systems with decentralized control and advanced connectivity (IoT functionalities). The consequence of this new technology for industrial production systems is reorganization of classical hierarchical automation systems to self-organizing cyber physical production system that allows flexible mass custom production and flexibility in production quantity.

- Industry 1.0(1784): Based on water and steam-powered mechanical production equipment.

- Industry 2.0(1870): Based on the division of labour and mass production through the use of electrical

- Industry 3.0(1969): Based on the use of electronic and information technologies to further automate

- Industry 4.0(nowadays): Based on the use of cyber-physical systems to lift the boundary between the real and the virtual

WEF and Industry 4.0

The Fourth Industrial Revolution represents a fundamental change in the way we live, work and relate to one another. It is a new chapter in human development, enabled by extraordinary technology advances commensurate with those of the first, second and third industrial revolutions. These advances are merging the physical, digital and biological worlds in ways that create both huge promise and potential peril. The speed, breadth and depth of this revolution is forcing us to rethink how countries develop, how organisations create value and even what it means to be human. The Fourth Industrial Revolution is about more than just technology-driven change; it is an opportunity to help everyone, including leaders, policy- makers and people from all income groups and nations, to harness converging technologies in order to create an inclusive, human-centred future. The real opportunity is to look beyond technology, and find ways to give the greatest number of people the ability to positively impact their families, organisations and communities.

As it prepares to embark on a massive digital transformation, India’s ability to fully capitalize on the emerging technologies of the Fourth Industrial Revolution will be one of the leading

drivers of global prosperity and peace in coming decades. To ensure India’s success in this capacity, the creation of a Centre for the Fourth Industrial Revolution in India dedicated to the Fourth Industrial Revolution was announced by Prime Minister Narendra Modi on 23 January 2018 at the World Economic Forum Annual Meeting.

Implication of industry 4.0 on Management Education

Over the last 250 years, we have experienced four different industrial revolutions that have changed our understanding of humanity from head to toe. With the Industry 4.0 education revolution, we are entering a new era (Education 4.0), where learning must also change entirely!

We are currently witnessing the fourth industrial revolution, aka Industry 4.0, where technology (artificial intelligence) is the primary driver. Thus, the current business schools must adapt in order to match with these changes. Recent studies by the World Economic Forum (The Future of Jobs & Skills) in 2018 and IFIM – NHRDN (Curricula 4.0 – Creating Future Managers) in 2019 indicate a gap between what is being taught and what the industry expects / demands.

The b-schools must focus on including courses that can help fill the industry-academia gap:

- Courses on cross-cultural communication enabling the students to collaborate virtually and be productive

- Courses on innovation, design thinking, and decision-making to shape a design mindset

- Courses on self-development, wellness & fitness, business communication (oral & written) improving social intelligence

- Courses on digital business & strategy, business science, and business economics to help build adaptive thinking

- Courses on business tools and integrative courses in business strategy to promote computational thinking

- Involve students in institutional projects, social immersion projects, industry internship programs, and global immersion projects.

- Supplement classrooms with AI-enhanced assessments, VR powered simulations, digital notes, and digital lectures, etc.

Future workers must be well-trained in emerging technologies and values associated with those technologies. The b-schools need to continuously reinvent and evolve with industry 4.0 to avoid “shortage of skills” in the near future.

Industry 5.0

The term Industry 5.0 refers to people working alongside robots and smart machines. It’s about robots helping humans work better and faster by leveraging advanced technologies like the Internet of Things (IoT) and big data. It adds a personal human touch to the Industry 4.0 pillars of automation and efficiency.

The objective of Industry 4.0 is to interconnect machines, processes and systems for maximum performance optimization. Industry 5.0 takes such efficiency and productivity a step further. It’s about refining the collaborative interactions between humans and machines.

Currently, two visions emerge for Industry 5.0. The first one is “human-robot co-working”. In this vision, robot and humans will work together whenever and wherever possible. Humans will focus on tasks requiring creativity and robots will do the rest. Another vision for Industry

5.0 is bioeconomy [7]. Smart use of biological resources for industrial purposes will help to achieve a balance between ecology, industry, and economy. According to the European Commission, bioeconomy is “the production of renewable biological resources and the conversion of these resources and waste streams into value-added products, such as food, feed, bio-based products, and bioenergy. It includes agriculture, forestry, fisheries, food, and pulp and paper production, as well as parts of chemical, biotechnological and energy industries.

Transition from Industry 4.0 to Industry 5.0

Industry 4.0 chiefly discusses digitalization focus on adoption of digital technologies such as internet of things, big data, artificial intelligence, blockchain, and cloud computing. Those technologies bring out the capability for adaptive and agile organization to focus on customer experience. While companies are struggling in handling the emerging technologies and agility in Industry 4.0, they need to start to think about the transition into Industry 5.0. Even though both industry 4.0 and 5.0 have kept technology as the centre of their respective businesses, to sustain their business the firms will need to provide agility in organization to involve technology in fulfilling customer aspirations. Industry 5.0 focus on human-centered technology (Fujii, Guo, & Kamoshida, 2018; Onday, 2019). Industry 5.0 provides smart community and

Collaboration between people, and smart technology to take over the manual and repetitive tasks integrating with human creativity to elevate

It seems that when we were finally understanding, implementing and getting used to industry 4.0, the term 5.0 came about. When did this happen? Why so fast? We may even think: “I’m not even finished adapting to Industry 4.0! Does this mean that I have to start from scratch all over again? So soon?” The answer is no. There is no need to discard or forget Industry 4.0 to be a part of Industry 5.0 This happens because Industry 4.0 and Industry 5.0 are mutually complementary, not mutually exclusive.

Regardless of our industry or line of work, we’re currently experiencing historically high rates of change. These changes have become part of everyone’s everyday life.

Industry 4.0 brought advances that allowed intelligent machines and other technological equipment to do much of the work in factories and production facilities.

However, between March and April 2020, entire production chains all over the world came to a standstill due to the COVID-19 pandemic.

If the disease only affects humans, why didn’t the machines continue to do their job?

This moment helped us reflect on the role and importance of humans in the job market. We realized that even though machinery and equipment can operationalize tasks, all industries still need people.

As most of the planet went through this process in early 2020, Japan had gone through a similar process several years ago.

This situation led the government to question existing technological advancements and move from “what is disrupting our way of life today?” to “what will disrupt our way of life tomorrow?” The recognition of the need to think ahead is what brought Industry 5.0.

Industry 4.0 focusses on the interconnectedness of machines and systems in order to achieve optimum performance to improve efficiencies and productivity. Industry 5.0 is touted as taking it a step further and refining the interaction between humans and machines. What we’ll see is greater collaboration between the two: the ultra-fast precision of automated technology works with a human’s critical thinking skills and creativity.